Polished concrete

A growing popular floor solution is a polished concrete floor. It is achieved by grinding the concrete up to a 400-1500 grit finish depending on your choice of lustre. There are also different stain options to change the colour of your floor.

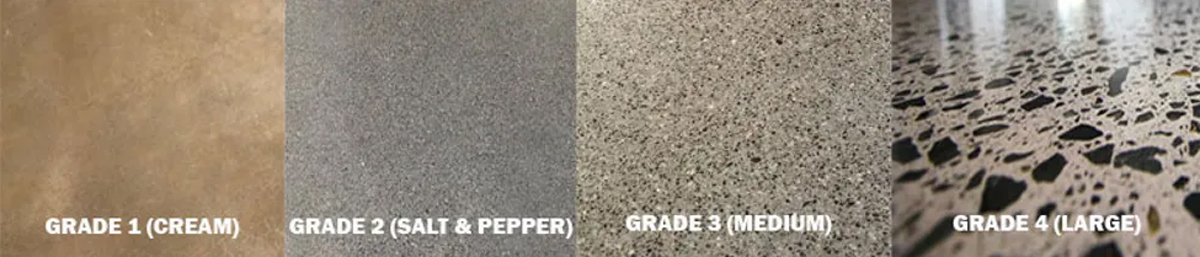

Grind Depths

Grind and Seal

A single step grind and seal using a carefully chosen sealer best fit for the environment and application.

Stained Concrete

Polished concrete floors can be stained a variety of colours and patterns to achieve different looks or designs.

Maintenance And Repairs

Repairs are possible in polished concrete, however local repairs will not match original area due to time and wear. Daily maintenance includes sweeping or vacuuming loose debris and mopping with warm water.